PRODUCT

LIST OF CONSUMABLE MATERLALS

LASER MARKING MACHINE(R&D)

강판, 코일, 슬라브(Slabs), 빌레트(Billet), 형강, 파이프 건설자재등의 생산라인이 다품종화 되고 있으며 물류의 자동화, 합리화에 따라 대상재마킹작업은 수작업에 의존해온 인자작업이 아닌 자동마킹시스템을 도입, 적용하고 있습니다.

이에 각종마킹 대상재에 대한 적절한 기계장치와 도료잉크를 준비하여 물류관리용 마크, 제품마크에 대응하는 토탈마킹 솔루션을 제공하고 있습니다.

MARKING MACHINE 특징

| NO | 기계구조 |

전용 TYPE |

A/S용이 SPACE 부품구입 용이 국산품 |

| 1 | 사용PAINT | 국산사용가능 | COST DOWN효과 |

| 2 | NOZZLE형태 | 순환CLEANING고온형 | 고온, 내구성 탁월 |

| 3 | MARKING HEAD구조 | LM GUIDE & BALL SCREW방식 | 내구성 및 문자형내 재현성 용이 타업체는 WIRE TYPE=내구성불안 |

| 4 | 마킹대상면 감지장치 | 기계식 TOUCH | AIR CYLINDER & 간접 BAR접촉방식으로 고온에 이용 |

| 5 | 제어시스템 | PLC 직접제어형 | 운전 및 A/S용이 |

| 6 | 문자형태DOT형태 | DOT형 CHARACTER방식 | 선명하고 일정한 문자형태(문자가 퍼지거나 흘러내리지 않음) |

| 7 | 국산화제작능력 & 설비유지 및 A/S 방안 | 설비 국산화 | 직접설계, 제작, 설치, 시운전 및 A/S, MAINTENANCE 할 수 있는 능력보유 |

| 8 | MARKING M/C 주요설비 조달방안 | 국산으로 바로가능 긴급조달 가능 | 타사제품은 국내에서 직접 제작하지 않으므로 다소의 시간 필요… |

| 9 | 납품실적 및 시장점유율 | POSCO,주요철강업체 국산화 제품납품 | POSCO고온소재 MAKING MACHINE은 100%자사제품 사용 |

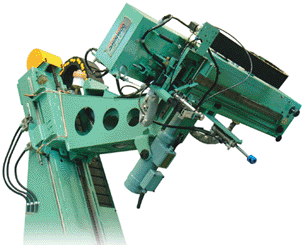

MARKING MACHINE 종류

MARKING MACHINE 구성

1. MARKING 본체

– MARKING HEAD

– 이동기기(종행,횡행,상하)

– 근접 S/W등

DESCALING 장치

고압속 분사 및 기계적 충격방식

2. PAINT 공급장치

– TANK

– PUMP

– 교반장치

3. 기기 조작반

– 기기 수동 제어 PANEL

4. 제어판

– PLC 등 제어기기 내장

– 상위 COMPUTER와 연결

– MMI 내장

Marking System의 응용

윗면에 마킹

측면에 마킹

내면에 마킹

코일에 마킹

NOZZLE & NOZZLE CONTROLLER

마킹노즐을 서보시스템이 장착된 X-Y스테이지(Stage)에 의해 문자형태에 맞추어 이동시키면서 일정거리를 이동할 때 마다 노즐을 개폐하고 도료를 분사함으로서 마킹을 하는 방식입니다. 따라서 분사하는 시간 간격을 좁히면 연속된 선문자가 되고, 시간 간격을 넓히면 도트문자가 됩니다.

- 한개의 노즐을 X-Y축으로 문자를 형성하기 때문에 임의의 사이즈, 임의의 패턴문자, 마크를 인 자할 수 있습니다.

- 문자 형태의 설정, 변경은 모니터 화면을 통해서 할 수 있으므로 문자인식 System 적용에도 용이합니다.

- 소형문자의 마킹도 가능합니다. 20mm(H) x 15mm(W)

- 아토마이즈(atomize)방식의 노즐을 사용하고 있기 때문에 열간재에 대해서도 도료 소비량은 다른 방식에 비해 적어집니다.

- 대상이 되는 재료는 온도 정보에 의해 도료분사량을 컨트롤하고, 일정한 굵기의 문자를 마크할 수 있습니다.

- 노즐의 막힘 현상을 방지하는 구조를 가지고 있습니다.

| Product Name | BEARING HOUSING |

| Model | SWI-IDNMM-BH-A01 |

| SPEC | 1000Pulse |

| Material | Bearing Housing BKT SS400 |

| Usage | Marking Machine |

1 NOZZLE MARKING MACHINE

1개의 마킹노즐을 서보시스템이 구축된 X-Y Stage에 장착하여 원하는 문자(특수문자 포함), 로고등을 마킹하는 방식입니다.

| 마킹대상재 | 슬라브, 블름, 빌레트, 후판재, 열연코일 |

| 표준 스테이지 | A형 - X축 600mm x Y축 200mm |

| B형 - X축 600mm x Y축 200mm | |

| C형 - X축 600mm x Y축 200mm | |

| D형 - X축 600mm x Y축 200mm | |

| 문자 사이즈 | 문자높이 20mm 이상의 임의의 사이즈 |

| 마킹속도 | 0.7초/문자 (H=30mm P=30mm) |

| 문자 굵기 | 3mm 이상 |

| 노즐 거리 | 3mm ±5mm |

| 마킹되는 재료의 온도 | 상온 ~ 1100℃ |

| 도료 | 수성 페인트 |

| 탱크 용량 | 50L (표준) |

| 데이터 설정 방식 | 매뉴얼 설정 및 자동 링케이지 설정 |

| 전원 | AC200V/220V 또는 440V 50/60 Hz |

| 압축 공기압 | 400kPa (4kgf/㎠) 이상 |

| 디스케일링 수 | 150~300L/min at 1.5~2.0Mpa (15~20kgf/㎠) |

| 세정수 | 100~200kPa (1~2kgf/㎠) |

PEN MARKING MACHINE

펠트펜(Felt Pen)에 필요량의 잉크를 자동 공급하면서 펜기구부분을 X-Y-Z축으로 이동시키며 문자를 형성해 가는 방식입니다.

| 마킹대상재 | 후판재, 냉연코일 |

| 문자사이즈 | 폭 30mm 이상 |

| 높이 40mm 이상 | |

| 피치 35mm 이상 | |

| 문자의 종류 | A~Z 영문자 |

| 0~9 숫자 | |

| 기타 특수문자 | |

| 마킹속도 | 1문자 1초 이내 |

| 문자수 및 줄수 | 자유로이 선택 |

| 마킹 재료의 온도 | 상온 ~ 250℃ |

| 도료 | 유성잉크 |

SIDE COLOR MARKER(NON CONTACT TYEP)

후판재 측면에 Color 및 제품번호(바코드)등을 표시하는 장치입니다.

| clolr 마킹 | 대상재 두께 50mm 이하 |

| Color | 백색, 황색, 적색 (Standard) |

| 그 외 Color (특수) | |

| Side 마킹 | 문자 높이: 0.7~18.2mm |

| 폰트 크기: 5dot에서 2개의 24dot까지 | |

| 마킹속도 | 5.5mm/s 까지 |

| 문자작성방식 | INK JET NOZZLE |

| 마킹 재료의 온도 | 상온 ~ 350℃ |

MARKING TAG(1-NOZZLE MARKING & TAG TYPE)

| 구분 | 1-Nozzle |

| Model Type | Sad, Boom |

| 방식 | 1개의 마킹노즐을 서보 시스템이 구축된 X-Y Stage에 장착하여 원하는 숫자, 문자 등을 페인트 마킹하고, 라벨 프린터로 숫자, 문자, 로고, QR-CODE 등 제품의 정보를 인쇄하여 가스식 타정 공구로 제품에 라벨을 타정하는 방식. |

| 장비특성 | * Marking 품질이 우수하다. * 정비 포인트가 적다. * 대상재의 제한이 없다. * 문자의 크기 및 Marking 위치에 제한이 없다. * Label 부착 시 QR-CODE를 통해 제품의 정보 확인이 가능 하다. |

| 구성품 | * Marking & Tag machine (Advancing, Traveling, Nozzle assembly, Detector, Gas gun) * Paint unit * Discaler (Mechanical, water) * PLC Panel, Local Panel, HMI * Printer unit |

| 사용 도료 | 국산수성도료 |

| 마킹속도 | 1초/문자 H=30mm P=30mm |

| 문자 사이즈 | H 20mm 이상의 임의의 사이즈 |

| 문자 굵기 | 3mm 이상 (±1mm) |

| 재료의 온도 | 상온~1100℃ |

| 라벨 사이즈 | 가로 100mm, 세로 70mm |

| 가스건 핀 모재/길이 | 강철 / 14mm |

| 프린터 인쇄방식/모드 | 고온용 리본으로 인쇄 / 라벨 컷팅 모드 |

| 가동 조건 (압축공기) | 0.4MPa (4Kgf/cm³) |

MARKING TAG (7-Nozzle Marking&Tagtype)

| 구분 | 7-Nozzle |

| Model Type | Sad, Boom, Billet, Beam blank |

| 방식 | 7개의 Nozzle을 나열하여 종, 횡 또는 곡선 이동시켜 7X5의 매트릭스 상태로 도료를 분사시켜 페인트 마킹을 한 뒤 라벨 프린터로 숫자, 문자, 로고, QR-CODE 등 제품의 정보를 인쇄하여 가스식 타정 공구로 제품에 라벨을 타정하는 방식 |

| 장비특성 | * 7개의 노즐을 사용하여 작업시간이 짧다. * 대상재를 정지시키지 않고 작업이 가능하다. – 대상재 이송방식 (Non stop Marking 가능) – Machine 이송 방식(대상재 일시 정지) * Label 부착 시 QR-CODE를 통해 제품의 정보 확인이 가능 하다. |

| 구성품 | * Marking & Tag machine (Advancing, Traveling, Nozzle assembly, Detector, Gas gun) * Paint unit * Discaler (Mechanical, water) * PLC Panel, Local Panel, HMI * Printer unit |

| 사용 도료 | 국산수성도료 |

| 마킹속도 | 1초/문자 H=30mm P=30mm |

| 문자 사이즈 | H 20mm 이상의 임의의 사이즈 |

| 문자 굵기 | 3mm 이상 (±1mm) |

| 재료의 온도 | 상온~1100℃ |

| 라벨 사이즈 | 가로 100mm, 세로 70mm |

| 가스건 핀 모재/길이 | 강철 / 14mm |

| 프린터 인쇄방식/모드 | 고온용 리본으로 인쇄 / 라벨 컷팅 모드 |

| 가동 조건 (압축공기) | 0.4MPa (4Kgf/cm³) |